The Importance and Trends of Custom Packaging

In today’s highly competitive global market, custom packaging has surpassed its basic function of product protection and has become a crucial marketing strategy. Almost all the brands have started using custom packaging boxes as a way to differentiate themselves from competitors.

Custom packaging allows products to stand out, enhance brand image, and meet consumers’ demand for personalization. This article will delve into the importance of custom packaging and explore its current trends.

The Importance of Custom Packaging

In a thriving consumer market, standing out among numerous products is a challenge for manufacturers and retailers.

Packaging plays a vital role in this aspect. Well-designed and recognizable packaging not only grabs consumers’ attention on store shelves but also enhances their awareness and memory of the product.

Custom brandspackaging goes a step further by not only providing the basic function of protecting the product but also conveying the brand story, strengthening brand image, and leaving a lasting impression on consumers.

Trends in Custom Packaging

The packaging industry is moving towards further personalization and customization. Packaging is no longer just about wrapping a product; it needs to better express product attributes, brand image, and even consumers’ identity and lifestyle.

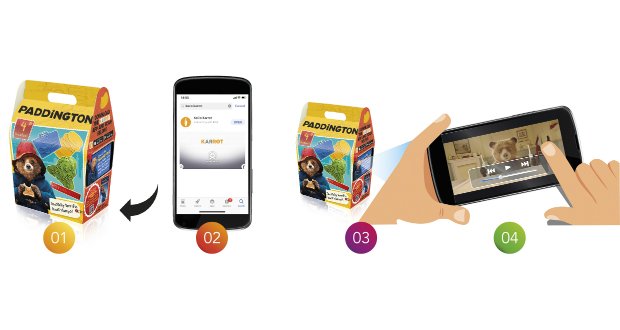

For instance, some companies are incorporating augmented reality (AR) elements into packaging, allowing consumers to scan the packaging with their smartphones to access additional product information or interactive experiences.

Enhancing Brand Image through Custom Packaging

High-quality custom packaging can serve as a powerful branding tool. Well-designed packaging boxes can enhance the perceived value of the product and help consumers recognize and remember your brand from the moment they see it.

Moreover, various design elements such as patterns, colors, typography, materials, and shapes can be cleverly utilized to communicate the brand’s values, attract and retain the target audience.

The Connection Between Brand Storytelling and Custom Packaging

Custom packaging allows brands to tell their stories and establish emotional connections with consumers. Design elements on packaging boxes, such as patterns, colors, and typography, can be used to convey the brand’s core values and narrative.

For example, brands with a rich historical heritage may choose a vintage design style on their packaging to visually communicate their history and traditions.

On the other hand, eco-conscious brands may opt for recyclable materials or emphasize natural and environmentally friendly elements in their packaging to showcase their commitment to sustainability.

Application Examples of Custom Packaging in Different Industries

With consumers’ increasing demand for personalization, custom packaging has found widespread application in various industries.

In the beauty industry, brands design different styles of packaging for different product lines to highlight product features and values, satisfying consumers’ pursuit of aesthetics.

In the food industry, personalized food packaging makes products more eye-catching on shelves, and beverages and snacks often feature interesting texts and graphics on their packaging, enhancing consumers’ purchasing experience.

In the electronics industry, sleek and elegant custom packaging showcases the high-end quality of the products, while the layout and design inside the packaging reflect meticulous protection and care for the product.

The custom packaging is widely used in many different industries, except the beauty industry, food industry, electronics industry, there are also have the industries of bakery, fast food, shipping, shopping, retail, pharmaceutical, flower, etc. Almost all the industries will use the custom packaging.

When creating custom packaging boxes, it is essential to consider not only innovative and appealing design but also material selection and manufacturing processes to ensure packaging quality and functionality.

Additionally, environmental factors should be taken into account to meet both personalization demands and sustainable development goals.

custom packaging plays an increasingly important role

In conclusion, custom packaging plays an increasingly important role in today’s market competition. It not only adds value to products and enhances brand image but also meets the growing demand for personalization among consumers.

However, the challenge lies in fulfilling these demands while achieving sustainable development. Looking ahead, with technological advancements and heightened consumer awareness, we can expect custom packaging to evolve with new trends and possibilities.

Environmentally Friendly Packaging for a Sustainable Future: Embracing a New Trend

As global environmental issues become increasingly severe, environmental sustainability has become a focal point of concern. In this context, environmentally friendly packaging has emerged as a new trend in the packaging industry. This article will provide a detailed overview of environmentally friendly packaging, including its definition, current status, future trends, and how to choose environmentally friendly packaging suppliers.

Definition of Environmentally Friendly Packaging

Environmentally friendly packaging, as the name suggests, refers to packaging with minimal environmental impact.

It primarily encompasses the following aspects: firstly, environmentally friendly packaging should be made from recyclable or biodegradable materials.

Secondly, the manufacturing process of environmentally friendly packaging should minimize its environmental footprint.

Finally, environmentally friendly packaging should contribute to reducing packaging waste.

Current Status of Environmentally Friendly Packaging

Driven by increasing consumer awareness of environmental issues and policy advocacy, environmentally friendly packaging has gained widespread adoption globally.

Many large companies have started utilizing environmentally friendly packaging as a means to enhance their brand image and fulfill their social responsibilities.

Additionally, with the development of new environmentally friendly materials and technologies, the variety and functionality of environmentally friendly packaging have expanded, catering to various needs.

Future Trends of Environmentally Friendly Packaging

Looking ahead, environmentally friendly packaging holds tremendous potential for development and market expansion. On one hand, as environmental regulations become stricter and consumer demands shift, there will be a greater demand for environmentally friendly packaging by businesses.

On the other hand, advancements in technology will drive innovation in environmentally friendly packaging. For example, new types of environmentally friendly packaging such as edible packaging and smart packaging will gradually integrate into people’s lives.

Choosing an Environmentally Friendly Packaging Supplier

When selecting an environmentally friendly packaging supplier, several key factors should be considered. Firstly, assess whether the supplier has the capability to utilize environmentally friendly materials and energy-efficient equipment.

Secondly, evaluate whether the supplier’s production processes align with environmental standards. Lastly, assess the supplier’s ability to continuously research and develop new types of environmentally friendly packaging.

Companies like Weifang Art Packaging, which not only possess advanced equipment and stringent quality control but also actively engage in the development of environmentally friendly packaging, are reliable choices for environmentally friendly packaging suppliers.

Case Study: Environmental Packaging Enhancing Brand Image

Among numerous environmentally friendly packaging suppliers, Weifang Art Packaging undoubtedly stands as a leading company. With a robust quality control system and strong customization capabilities, they provide satisfactory solutions tailored to customer needs.

For instance, an organic food production company aimed to highlight its commitment to the environment and health through environmentally friendly packaging. In collaboration with Weifang Art Packaging, they achieved results beyond their expectations.

Weifang Art Packaging designed an aesthetically pleasing and eco-friendly packaging box, which garnered positive consumer feedback and enhanced their brand image.

Challenges and Opportunities of Environmentally Friendly Packaging

Looking to the future, environmentally friendly packaging will face various challenges but also present significant opportunities.

Challenges primarily arise from the costs and technology associated with environmentally friendly packaging. As the costs of environmentally friendly materials and production processes are higher than traditional packaging, businesses need to address the challenge of maintaining environmental sustainability while controlling costs.

Additionally, exploring technological innovations to enhance the functionality and aesthetics of environmentally friendly packaging is crucial.

However, with society’s increasing focus on environmental sustainability and evolving consumer demands, environmentally friendly packaging will enjoy greater development space.

Government policy support for environmental initiatives and consumer preferences for environmentally friendly products will drive market demand for environmentally friendly packaging.

Technological advancements will also fuel innovation and improvements in environmentally friendly packaging, offering greater possibilities.

In conclusion, environmentally friendly packaging for a sustainable future has become a new trend in the packaging industry. Pursuing environmental sustainability provides opportunities for innovation and development.

As businesses, choosing a reliable environmentally friendly packaging supplier not only helps reduce our environmental impact but also enhances our brand image and market competitiveness.

The Path to Sustainable Custom Packaging Boxes

In today’s world, where environmental challenges are a global concern, more and more companies are focusing on environmental issues throughout their production processes.

Weifang Art Packaging as a leading company specialized in manufacturing custom packaging boxes in China, we have a responsibility and obligation to incorporate environmental sustainability into our production line. This article aims to discuss how we can achieve environmental sustainability in the production of custom packaging boxes.

Sustainable Materials Selection

First and foremost, let’s start with the material selection. An environmentally friendly custom packaging box should begin with the basic principle of choosing sustainable materials. So, what defines an eco-friendly material?

eco-friendly materials

In general, eco-friendly materials should be recyclable, biodegradable, and non-toxic. For instance, we can opt for using recycled paper, bamboo fiber, and other renewable materials in manufacturing packaging boxes.

Environmentally Friendly Production

Furthermore, for materials that cannot be recycled, we can mitigate their environmental impact by adopting more eco-friendly production processes.

Next, we need to focus on the environmental impact of our production processes. Traditional manufacturing processes for packaging boxes often involve the use of chemicals that can be harmful to the environment, such as certain printing inks and adhesives.

To achieve environmentally friendly production, we need to search for alternatives or modify our production methods.

For example, using water-based inks instead of solvent-based inks can reduce volatile organic compound (VOC) emissions and minimize health risks for operators. Additionally, we can consider adopting glue-free bonding techniques to reduce the use of chemical adhesives.

Environmental Sustainability of Packaging Design

The environmental sustainability of packaging design is also crucial. When designing custom packaging boxes, we can employ strategies such as reducing material usage and facilitating recycling to enhance their environmental footprint.

For example, we can design more compact and efficient packaging forms to minimize unnecessary material waste. Simultaneously, we can develop packaging designs that are easy to disassemble and sort for consumers, facilitating packaging recycling.

Energy consumption during the production process is another important environmental concern. Therefore, we need to continuously optimize our production line, improve energy efficiency, and reduce energy consumption.

Additionally, considering the use of renewable energy sources such as solar or wind power can provide sustainable energy for our production operations.

In conclusion, the journey toward environmentally friendly custom packaging boxes requires reforms and innovations in multiple aspects. Whether it’s material selection, production processes, or packaging design, each step carries our responsibility for the environment.

Achieving sustainable production is an ongoing effort that demands continuous improvement and dedication. In the following sections, we will delve deeper into these aspects.

Circular Economy Model

Environmental sustainability and the circular economy are closely intertwined. Shifting from a short-sighted, profit-centric linear production model to a circular economy model is an inevitable trend for the future.

The custom packaging box industry is no exception, and we must actively participate in the circular economy by improving product design and optimizing the recycling process to achieve the dual goals of environmental protection and economic benefits.

Eco-friendly Product Design

On one hand, we need to prioritize eco-friendly product design. This involves not only reducing material usage but also extending the product’s lifespan and ensuring ease of recyclability once it reaches the end of its life cycle.

For example, designing packaging boxes that can be disassembled and reassembled allows for easy separation and recycling of materials, further reducing environmental pollution.

comprehensive recycling system

On the other hand, we need to establish a comprehensive recycling system. We should actively collaborate with governments, non-governmental organizations, and communities to promote recycling initiatives while minimizing the difficulty and cost of recycling.

For non-renewable materials, we need to adopt scientifically sound disposal methods to minimize their environmental impact.

Furthermore, we should integrate environmental sustainability into every aspect of our company by establishing a complete environmental management system. This includes not only our production line but also internal management practices and marketing strategies.

Only when everyone realizes the importance of environmental protection and takes proactive action can we truly achieve sustainable.